Mechanical Drafting

Expert Mechanical Drafting Solutions | Precision & Excellence by Citotech Integrated Services.

Get Precise Mechanical Drafting With Targeted Design Solutions, Ensuring High Quality, Accuracy, And Efficiency To Save Time And Effort. Contact Us Today!

Citotech Integrated Services excels in delivering bespoke mechanical drafting solutions, expertly tailored to meet the precise requirements of industrial and engineering projects. Our team produces highly detailed, accurate technical drawings for mechanical systems, equipment layouts, and related components, ensuring unparalleled precision, clarity, and adherence to industry standards.

Mechanical drafting services are vital for the precise and efficient design and installation of mechanical systems in various industries. These services provide detailed technical drawings for mechanical components and systems, ensuring that the project is carried out according to the highest standards of accuracy and performance. Here’s why mechanical drafting services are important and the key aspects they cover:

Importance of Mechanical Drafting Services:

Precision in Design: Mechanical drafting services ensure that the designs of complex mechanical systems and equipment are meticulously detailed. This level of precision is crucial for the proper functioning of systems and components, preventing errors during manufacturing or installation.

Streamlined Communication: Detailed mechanical drawings communicate design intent and specifications clearly to engineers, manufacturers, and contractors. This eliminates ambiguity, ensures everyone is on the same page, and reduces the risk of misinterpretations or mistakes during construction.

Compliance with Standards: Mechanical systems must adhere to stringent industry standards and regulations. Mechanical drafting services help ensure that all designs comply with local, national, and international codes, ensuring both safety and efficiency.

Efficient Manufacturing and Installation: Accurate mechanical drawings serve as the blueprint for manufacturing components and assembling systems. These drawings allow manufacturers to produce parts to exact specifications, while installers can follow clear guidelines for system setup, reducing the risk of delays, errors, and cost overruns.

Cost-Effective Solutions: Properly drafted mechanical designs help optimize the use of materials and resources. By carefully planning the layout and functioning of mechanical systems, drafts can minimize waste, reduce unnecessary expenditures, and ensure that the project stays within budget.

Troubleshooting and Maintenance: Mechanical drafts provide invaluable documentation for troubleshooting and maintenance throughout the lifespan of the system. When issues arise, technicians can reference these detailed drawings to quickly diagnose and resolve problems, minimizing downtime and repair costs.

Key Aspects of Mechanical Drafting Services:

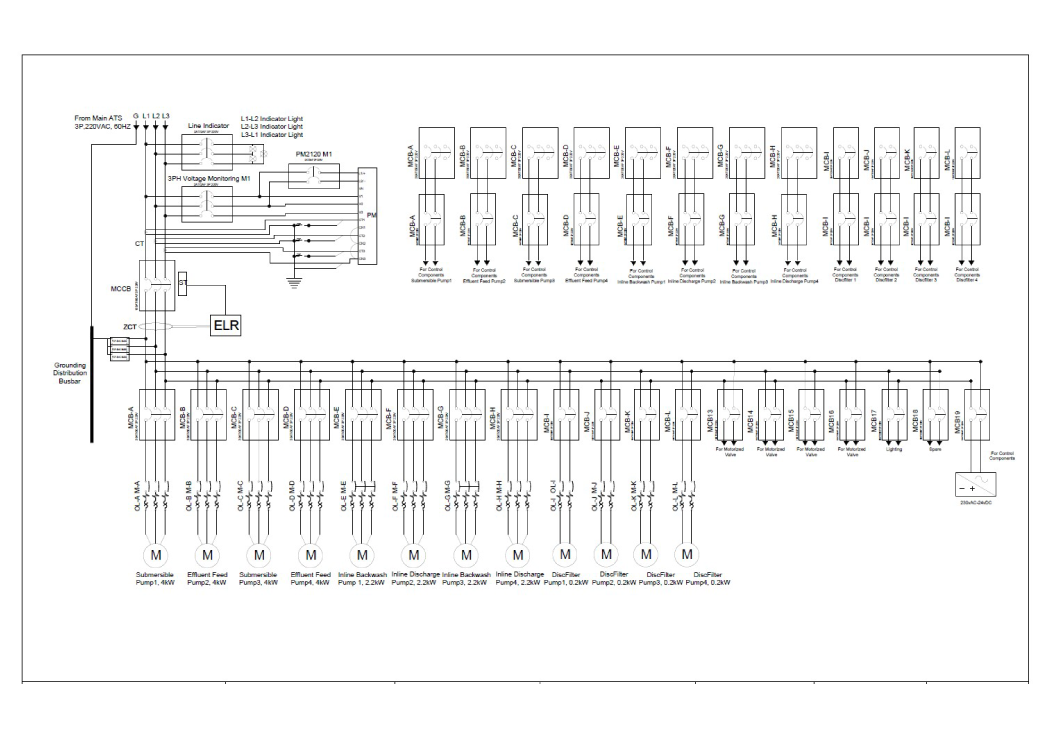

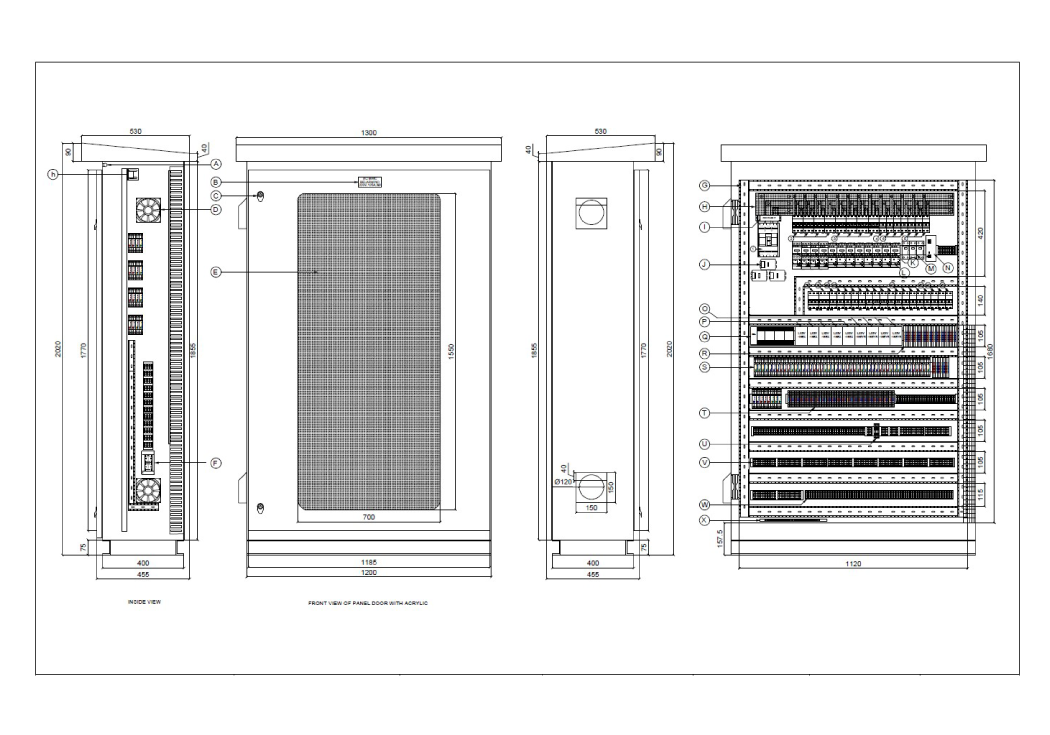

Mechanical System Layouts: These drawings show the arrangement of mechanical components and systems within a project, such as HVAC (heating, ventilation, and air conditioning), piping, and ductwork. They ensure that all components are positioned correctly for optimal performance and ease of access.

Equipment and Machinery Drawings: These technical drawings detail the design and specifications of individual mechanical components, such as pumps, motors, compressors, and gearboxes. These drawings guide the manufacturing process and ensure components are built to precise specifications.

Assembly Drawings: These drawings depict how individual parts fit together to form a complete mechanical system. They include details of connections, fasteners, and other crucial components, ensuring that the system is assembled correctly.

Piping and Plumbing Diagrams: Piping diagrams detail the layout of pipes, valves, and other plumbing components for fluid systems, including water, gas, and steam. These drawings are essential for ensuring the safe and efficient transport of fluids throughout the system.

3D Modeling and CAD (Computer-Aided Design): Modern mechanical drafting often involves 3D modeling and CAD tools, allowing for more advanced and interactive visualizations of mechanical systems. These models can simulate how systems will operate and identify potential issues before physical implementation.

Detail Drawings: These provide close-up views of specific parts or connections within a mechanical system, offering additional clarity on dimensions, tolerances, and material specifications. These drawings help ensure that every component is manufactured and installed correctly.

Assembly and Installation Instructions: For complex mechanical systems, detailed instructions on how to assemble and install various components are provided. These ensure that installations proceed smoothly and efficiently without overlooking important steps.

Maintenance and Operational Drawings: These documents provide essential information for the operation and maintenance of mechanical systems. They include schedules for regular maintenance, part replacement, and troubleshooting procedures, helping ensure the system’s long-term functionality.

As-Built Drawings: After the mechanical systems are installed, as-built drawings are produced to reflect any changes made during the installation process. These are critical for future maintenance and upgrades, ensuring that the system’s design is accurately recorded.

In summary, mechanical drafting services are essential for the accurate design, efficient manufacturing, and successful installation of mechanical systems. By providing clear, detailed, and standardized documentation, these services ensure that systems operate effectively, comply with safety regulations, and meet the specific requirements of each project. Whether for industrial or engineering projects, mechanical drafting services play a key role in ensuring precision, efficiency, and reliability in mechanical system design and execution.